Free Shipping On U.S. Orders Over $100 | 10% Off Entire Order On International Orders Over $300

- Bits & Bits Company

- CMT Orange Tools

- Hongdui Tools

- Jay's Custom Creations

- Katz-Moses Tools

- Rubio Monocoat

- Suizan Japanese Saws

- Dovetail & Joinery Tools

- Forged Hand Tools

- KM Tools Templates

- Measuring & Marking

- Router Bits and Forstner Bits

- Safety and PPE

- Sanding and Finishing

- Saw Blades and Table Saw Accessories

- Walnut Slabs

- Best Sellers

New Arrivals

Build Plans

- Build Up Initiative Plans

- Digital Content

- KM Tools Apparel

Woodworking Classes

- About KM Tools

Creator of the Week

- Katz-Moses Woodworkers with Disabilities Fund

- Partner With Us

- Free Router Table Plans

- Five Cut Method Calculator

- Linear Board Foot Calculator

- Wood Movement Calculator

Subscribe to the KM Tools Newsletter

Educational woodworking content, early access to new products, and flash sale discounts for subscribers only. Directly to your inbox. And did we mention a free copy of the Katz-Moses Router Table Build Plans ?

Cookie policy

I agree to the processing of my data in accordance with the conditions set out in the Privacy Policy.

Your cart is empty

2 Easy Ways to Remember Router Feed Direction (Quick Tip)

One of the most important aspects of router safety is getting feed direction right.

That means being aware of how you make cuts relative to the router bit’s rotation.

Essentially, you want the direction you push the router along the edge of a board to be the opposite of the bit’s rotational direction .

Cutting in the same direction as a bit’s rotation is called a climb cut — and if you’re not careful, it can cause the router to shoot out of your hands… or send the board you’re cutting shooting across the shop.

Overtime, cutting direction becomes second nature.

But when you’re first getting started, it can be a bit confusing (punny, I know). Especially if you’re switching between a handheld router and router table.

To make it easier, I’m sharing 2 easy tricks to help you remember router feed direction — until safety becomes second nature.

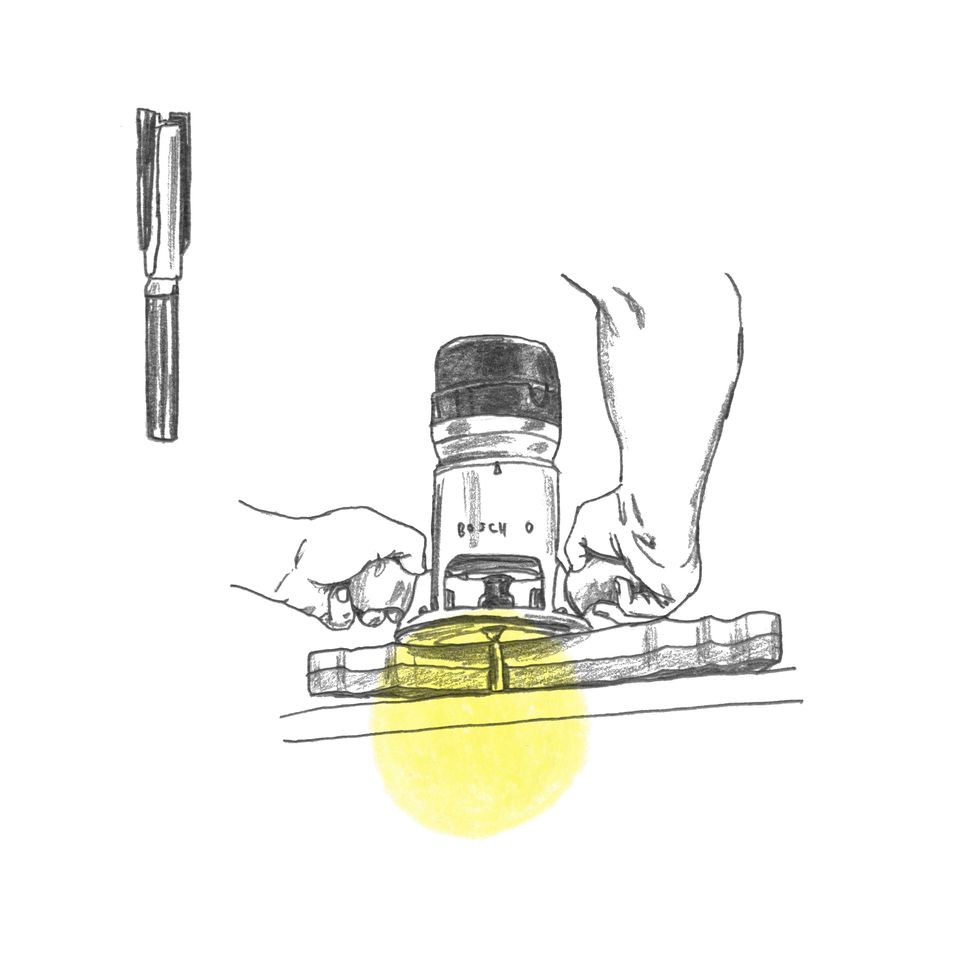

1. THE RIGHT HAND TRICK

When you’re first getting started, this trick is the easiest way to quickly remind yourself of the correct feed direction.

It uses your right hand — with your fingers and thumb representing different elements of the router.

Start by making a “thumbs up” sign with your right hand.

Your thumb represents the orientation of the router bit. So if you’re using a router table, point your thumb up. If you’re using a handheld router, point your thumb down.

The direction your fingers curve represents the router bit’s rotation. So whichever way they’re pointing is how the bit spins in that orientation.

(You’ll notice that for handheld routers the bit spins clockwise, and on router tables it spins counterclockwise).

Your feed direction should be the opposite of whatever direction your fingers are pointing.

So whether you're pushing a handheld router — or pushing a board over a router table — the direction that the board’s edge moves along the bit should be the opposite of that bit’s rotation.

For example, say you’re cutting a rabbet in a board with a handheld router. Make a “thumbs down” sign next to the edge you’re cutting and look at where your fingers point.

Push the router the opposite way through the cut — and you’ll have all the control you need!

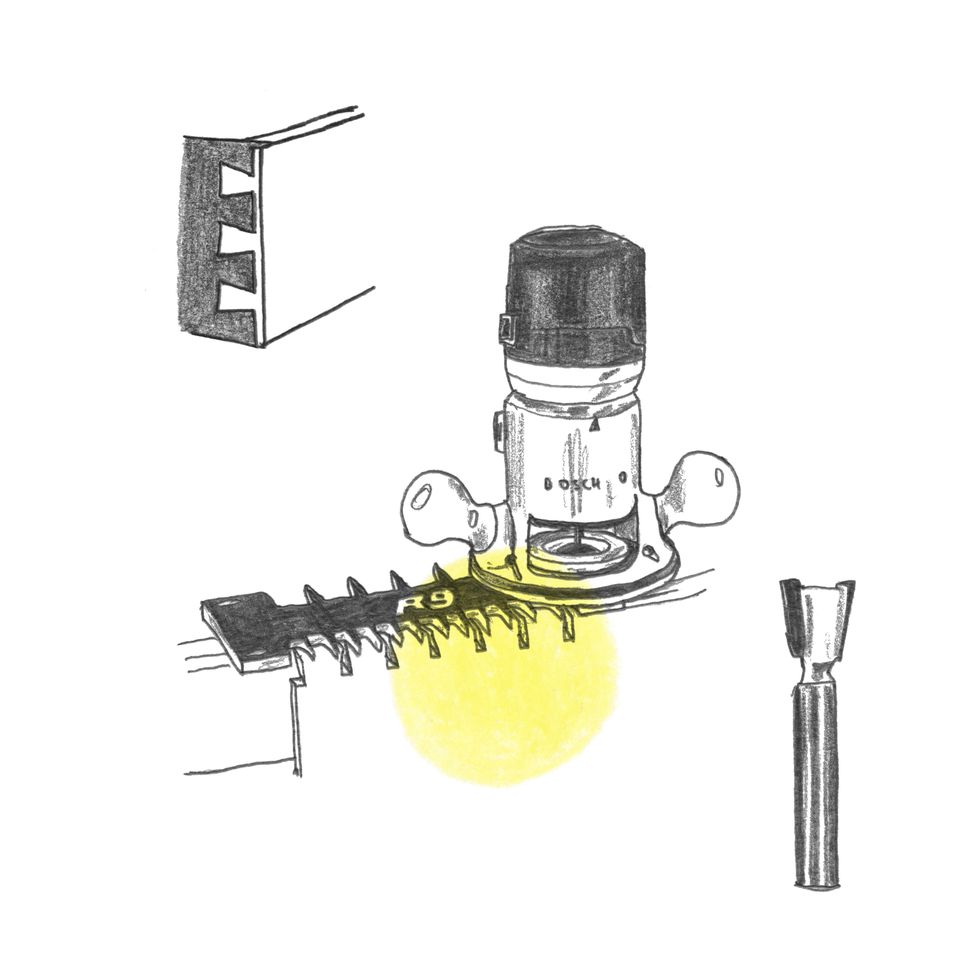

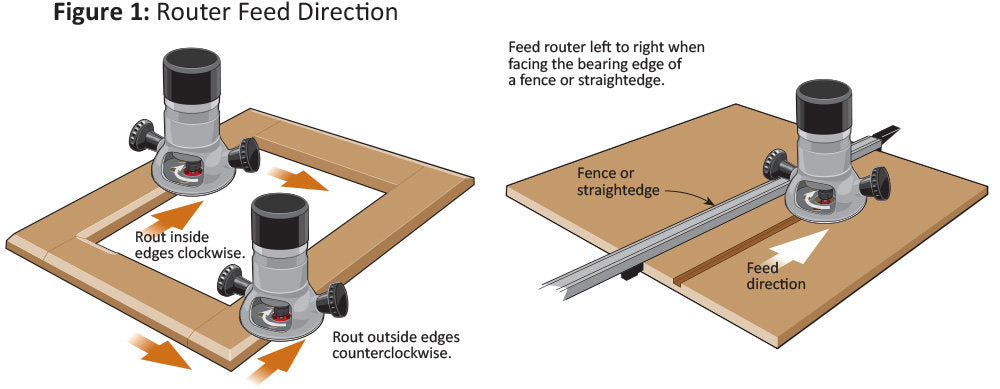

2. THE PICTURE FRAME CLOCK

This method isn’t as intuitive as the right hand trick, but can still be a good frame of reference (dang it, another pun).

Imagine you’re rounding over the edges of a picture frame.

For a handheld router , you want to push the router:

- Counter clockwise on the outside edge of the frame

- Clockwise on the inside edge of the frame

On a router table, you can think of the same directions — but now you're moving the workpiece instead of the bit.

So on a router table you’d rotate the workpiece :

- Counter clockwise for the outside edge of the frame

- Clockwise for inside the inside edge of the frame

The clockwise/counter clockwise idea remains the same. What changes is whether you're rotating the router or the actual board .

Just remember:

- Outside edge = Counter clockwise

- Inside edge = Clockwise

For handheld routers that rotation refers to the actual router, while on router tables that rotation refers to the workpiece.

Cutting with the correct feed direction will give you greater control with your router — keeping you safe as you build.

And with the two tricks above, you’ll have no problem remembering… until you get enough experience to just know.

Want more router safety tips? Read this.

Got your own trick for remembering feed direction? Let us know in the comments below!

Follow us on Instagram @katzmosestools , on TikTok @katzmoseswoodworking , and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

Continue reading

6 Tips for Starting Hand Saw Cuts (Quick Tip)

How to Flatten Slabs and Wide Boards with a Router Jig

I’ve been struggling with my router for years. This was a very good explanation. Totally helpful! Thank you.

David Meadow

I use the left to right method. When facing the piece, cut from left to right. Doesn’t matter if you are holding the router or it’s in a table.

Thanks JKM, another great article. The “right hand trick” I learned for handheld routers is; make an “L” with your right thumb and index finger like a kid makes an imaginary pistol. Then with your palm facing down touch your thumb to the edge you want to rout. Your finger points the way of the router. Works for inside and outside edges. We used the “thumbs up” for a reminder of bit rotation on the router table.

I had trouble routing a wide blind slot (both ends blind) – I hog out as much as possible with a forstner bit – drilling each end of the slot oversized to drop the piece over the router bit – then cut each side – problem is should I cut the between the bit and fence or the side opposite of the fence?

Maybe I need to glue up two pieces of wood with spacer blocks then plane, joint and cut to size…

Tom Albertson

Food for thought: if you change the “right hand trick” to the “left hand trick” then your fingers would point in the feed direction. Maybe easier to remember if you want to know which way to push the router/work piece and don’t care which way the bit spins. (No, I’m not left handed.) In any case, this info is great! Thanks!

Jim A. Paschis

The picture from interior and exterior surfaces present a good example for router feed directions. When advancing toward the next 90 degree piece with the exterior edge extremely thin there is a chance for corner tear out. For crucial, delicate work a protective piece can be clamped and routed.

Joseph Lowe

EXCELLENT! This really should not be difficult, and it’s embarrassing how many times I’ve had to figure this out moving between routers, particularly if I haven’t routed in a couple of weeks. Many thanks.

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Sign up and receive free build plans for the Katz-Moses Router Table as well as exclusive access to:

- Early notifications for upcoming product launches

- Sales and discounts on our most popular products

- Weekly educational woodworking content

What Router Direction Should You Use (Clearly Explained)

The router direction can make a big difference between nice, smooth cuts or dangerous cuts with an increased risk of accidents and uneven and untidy edges. But what is the correct router cutting direction?

The correct router direction is always in the opposite direction of the rotating router bit. When you know that a router bit always turns clockwise, you will understand that you have to push the router in the opposite direction.

In this article, you will get a good idea of which direction to use a router , depending on whether you are using a handheld router or router table. In addition, there are some router cutting direction exceptions, which you will understand after reading all the useful information you can find below.

Disclosure: At zero cost to you, I may get commissions for purchases made through links in this post. I earn from qualifying purchases as an Amazon associate. Products featured are selected based on quality, performance, and reputation, regardless of affiliate relationships.

What happens when using the wrong Router Direction

If you use the wrong handheld router direction or the wrong feed on the router table, the routerbit will push itself away from the wood you want to work . Due to the high router bit speed , this will make the router difficult to handle and make sudden uncontrollable movements that can be very powerful.

When using a handheld router, the router can be pulled out of your hands and the router bit can cause injuries. With a router table, the material will be pulled out of your hands or your hands will pull towards the router bit.

Whatever you use, hand router or router table, feeding the wood incorrectly can cause serious injury . In the least bad situation, you will end up with an uneven and messy-looking edge.

When working with cutting tools, there is always a risk of injury. Be well-prepared and set up a first aid kit in your workshop. You can read how to do this in my article How To Make A Workshop First Aid Kit – N°1 Guide | FREE CHECKLIST

Understanding Router Direction

To know which direction to use a router bit into the wood (hand router) or the correct input of the wood into the router bit (router table) , you must first know in which direction the router bit will rotate.

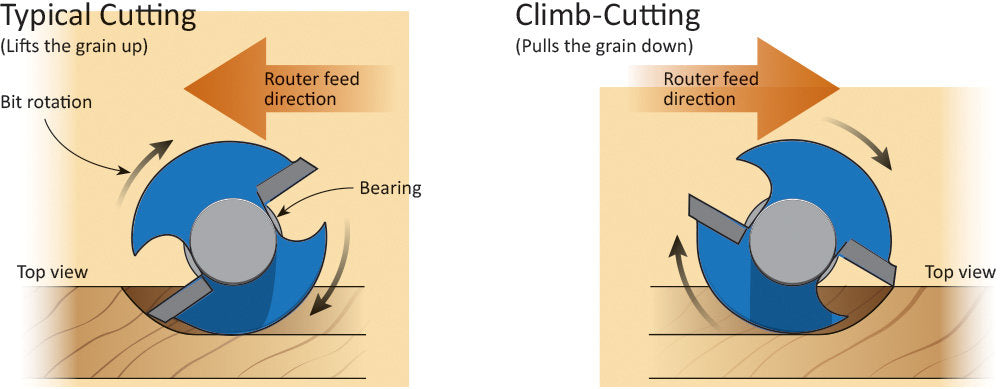

The correct router cutting direction is always against the direction of rotation of the router bit. This way, the router bit will cut into the wood (conventional cut) instead of pushing the wood away (climb cut). I’ll go into this in more detail in a moment.

In a handheld router, the router bit rotates clockwise, so if you have to enter it in the right way, the feed direction is usually from left to right. Please note , there are exceptions to this rule, which I will discuss further in this article.

When using a router in a table or mounted on a worktop, the direction of rotation of the bit changes. By mounting the router upside down , the router bit now rotates counterclockwise. As a result, the feed direction will often be right to left.

What is a conventional cut

The most secure cut is the conventional cut. The feed is in the opposite direction as the rotating cutter. In other words, a conventional cut is made by turning the router bit clockwise and pushing the router from left to right.

What is a climb cut

The climb cut is the opposite of the conventional cut. The wood is fed in the same direction as the rotary router bit. So when the router bit is turned clockwise, and you move the router from right to left, you make a climb cut.

The climb cut is therefore the unsafe way to work with the router. Because the router moves in the same direction as the rotating router bit, it will tend to push itself away from the wood instead of cutting into it. Due to the shedding, the router bit will therefore move away from the wood and thus make a “climbing” movement, hence the name climb cut.

Different router feed directions for handheld routers

From all the information you could already read, you now know that when milling along an outer edge with a hand mill , you always have to work from left to right, against the rotation of the mill (conventional cut).

This is the safest way to work with a handheld router and will result in a smoother cut.

However, there are sometimes exceptions to this rule. For example , if there is a chance that wood will break out on the corner, it can be good to make a short climb cut to prevent this. After that, you can continue with the conventional cut.

There are other situations where the push direction of the router is different. Below I will explain all possible router directions briefly and clearly.

Routing along the outer edge

This is the most common situation you will face. When you have a workpiece that you need to mill the outside of, always move the router counterclockwise.

Routing inner edges

Here you have to think the other way around. Remember that the bit always turns clockwise, so you have to push the router in the opposite direction.

When milling along the inside edges of a piece of material, you should work in a clockwise direction. this will allow the router bit to cut into the wood.

Routing a circle or arc

Although the circle has a different shape than a square workpiece, the method is the same. When milling an arc or circle with a handheld router, always move counterclockwise.

Routing a groove through the material.

When milling a groove through the center of a workpiece, there will always be material on both sides of the cutter. So you will wonder what the correct router direction is for this.

Well, if you’re cutting a freehand groove there’s really no right answer to this question. Any direction you use is the correct push direction since the router always has one side that moves with its rotation and one side that moves against its own rotation at the same time.

However, do not try to change the feed direction abruptly at any time, as this may cause the router bit to unexpectedly engage the wood and make uncontrollable movements.

However, if you are using a guide/side stop it is a good idea to choose the direction where the router bit always pulls the router towards the guide, thus avoiding climb cuts where the guide comes loose from the wood.

Different router feed directions for router tables

Routing an outer edge.

When milling an outer edge with a stationary router, you must feed the material from right to left, as you could read earlier in this article.

Making a reverse feed motion is dangerous and increases the risk that the bit will pull the material out of your hands and your hands may come into contact with the router bit.

Route a groove through wood

As with milling a groove with the hand mill through the center of a workpiece, the router table will always have material on both sides of the mill.

So the correct direction for milling a groove with the router table is the direction where the bit always pulls the wood against the fence . This way you avoid the wood being pushed away from the fence by a climb cut.

The router bit rotates clockwise at all times. All you have to do is run the router counterclockwise to cut into the wood . This allows you to make the safest cuts while also ensuring that the cut is always nice and smooth.

If you want to learn more about how to get the most out of your router , I recommend reading my article, How To Use A Router – Easy 5-Minute Starter Guide .

How to build your workshop on a budget?

Building your workshop can be daunting, filled with trial and error. Believe me, I’ve been there too. But it was “The Ultimate Small Workshop” course, a gem I discovered and now endorse on Christofix.com , that provided insights unparalleled to any other. This expertise empowered me to invest wisely and save substantially.

I really suggest it to all of my fellow DIYers and creators!

I hope this information about the correct router direction was helpful, and that this blog inspires you. Feel free to share this blog on Facebook, Pinterest, or other social media . You can do this by using the buttons below or at the top of the blog. It will be much appreciated. I’m looking forward to seeing you soon in another blog or video. Greetings, Christophe, founder of Christofix.com Woodworking | DIY | Home decoration

Meet Christophe - Founder & Woodwork Artisan Behind Christofix.com

Hi, I'm Christophe. With a daily dedication to woodworking, my expertise has grown immensely since starting in a modest garage in 2018. Today, I'm a recognized figure in the woodworking community, sharing daily insights and techniques at Christofix.com for enthusiasts at all levels, emphasizing sustainable and artistic woodworking.

Router Tips

Direction of feed.

When using a router it is important to know the correct direction of feed. The following guidelines will help you to determine this.

Router Direction

Always feed into the cutter, never with it. Routers generally run clockwise when hand held, and counterclockwise when turned upside down in a table.

Check Before Cutting

The easiest way to make sure you are doing things right with the table-mounted router, is to get your eye at table level and look at the bit. You will want to push stock into the bit so the carbide cutting edge hits the material first. When you are looking at the bit at table level notice where the carbide edge is and make sure you push the stock toward that edge, and NOT toward the back of the bit.

Cutting Outside Edges

Cutting Inside Edges

Home Articles Basic Links Projects Reference Tips & Tricks Tool Reviews Video Woodturning Contact About Us

This is a Veteran Owned site

Confusion is easy!

Text and photos by Tom Hintz

Considering that the router is one of the most popular woodworking tools, it is no surprise that questions regarding its use are common. Of nearly 300 email questions in my "hold" folder, 188 of them related to basic router use. What is especially interesting is that the majority of these questions involve feed direction and rates, both of which are crucial to safety and the quality of the cut.

Feed Direction and Danger

The good news about feed direction is that with very few exceptions, the stock always moves against the rotation of the bit. The bad news is that making a mistake with feed direction can easily initiate a very dangerous kick out with little or no warning.

Feeding the material against the rotation of the cutter affords control because the cutting action creates resistance to the force being applied by the operator to move the wood across the bit. This balance of forces makes controlling the wood much easier.

If the wood is introduced in the same direction as the bit is rotating the cutting edges instantly become extraordinarily efficient high-speed power feeders that can suddenly eject the wood, leaving the operators empty hands dangerously close to the cutter. This situation is particularly dangerous because the force the operator was applying to the wood before it kicked out immediately causes the now empty hands to lurch toward the bit. Disaster can be the instantaneous result.

Confusion Is Easy

It is apparent that the most frequent cause of feed direction errors is operator confusion regarding which side of the cutter, in relation to the operator, is turning which way. The router is the only commonly used wood working power tool that can be used with the cutter facing up in table-mounted situations, or down for hand-held operations. When router orientation is changed from bit up to bit down modes, the operator has to remember that feed directions change as well.

For clarity in this story, the "rear" of the bit is the cutting edge farthest from the operator and the "front" refers to the edge closest to you.

Consistent Practices

The easiest way to reduce feed direction errors is to develop standard operating procedures used each time a task is performed. Taking the time to double check the feed direction before each operation is a very good habit to get into.

Hand-Held Operations

I always start at the lower left corner of the piece when cutting the outside edge in the hand-held mode. The bit is spinning in a clockwise direction from my perspective so engaging the rear of the bit with the wood means the router always moves left to right and goes around the remaining sides of the piece in a counter clockwise direction.

When routing an inside edge, like when cutting the inside edge of a frame or opening, I start at the upper left corner so the rear of the bit again engages the wood and the router moves left to right. The only difference is that when cutting the inside edge, continuing the left to right motion takes the router around the opening in a clockwise direction.

Using the same starting point every time develops a habit that goes a long way towards preventing directional errors and the damage and danger that can create.

The exception to this would be when therre are end grain sections that are to be routed. Generally, we route the end grain segments first, and then the rest of the piece so any chipping that occurs at the end grain is removed in the final passes. I usually do the end grain first, then start at my normal position and go all the way around the piece, including a second pass over the end grain segments, so I get nice clean transitions from one side to the other.

Router Table Operations

safety note: whenever routing pieces on a router table be sure to use proper push stick, pads or other safety equipment that keep your hands a safe distance from the cutter..

When the router is installed bit-end up in a router table, bit rotation from the operators perspective is counter-clockwise. When using a fence or miter guide, the edge of the cutter closest to the operator is used and the material is fed right to left.

An exception is when cutting a centered slot in a piece of wood. The first pass is made by holding the wood against the fence and then plunging it down over the bit at the start point and then feeding the stock into the cutter from right to left. However, when the piece is reversed to make the second pass to center the slot, the rear edge of the bit is often doing the cutting. In this case, the piece has to be fed from left to right.

When making this type of cut, I have found it safest to make the first pass (right to left) and then shut off the router. I reverse the work piece and hold it in position above the router bit to make sure which edge of the bit will be doing the cutting. If the rear edge of the bit is doing the cutting, the work piece has to be fed across it from left to right.

It should be noted that cutting centered slots on a router table is always a difficult and somewhat dangerous operation. If you are at all unsure of your skills or safety equipment, make the slot by drilling holes at either end and then removing the material between them with a jig saw.

Occasionally router bits equipped with bearings are used in the router table without the fence. We have to remember that the router bit rotation is counter clockwise and adjust feed directions accordingly. When the front edge of the bit is used, the stock is fed right to left. If the rear of the bit is engaged, feed direction is left to right.

Remember to use the proper push sticks or pads to keep your hands far away from the bit. Without the fence, the bit will be totally exposed if the wood kicks out or breaks.

Climb Cutting

There are two situations when climb cutting, moving the router in the same direction as the bit rotation is acceptable. Climb cutting is always difficult and care must be taken to maintain control of the router.

The most common climb cut is on a dovetail jig with the router in the hand-held position. A small portion of the cutters edge is used to make a very light scoring cut, moving from right to left, to reduce tear out. Even though very little of the bit is engaged in the wood, care must be taken to maintain control of the router as it could want to accelerate down the wood.

The other situation when climb cutting is used is when using some laminate trimmers. Feeding the router against the bit rotation sometimes causes these materials to "chip" ahead of the cutter. In these cases, the laminate is trimmed as close to the base material as possible with other tools and then the router can be used to clean the edge, moving it in the same direction as the bit rotation.

Whenever climb cutting, whether on a dovetail jig or trimming laminates, keep the cuts very light and a firm grip on the router to avoid having it get away from you. Climb cutting without using proper procedures is very dangerous.

Determining the proper feed rate for any bit is relatively easy, assuming the router speed is set correctly for the bit. If the bit burns the wood, the feed rate is too slow. If the wood chips or blows out ahead of the bit, the feed rate is too fast. Granted these are generalizations and there are other factors that could contribute to these problems, but they remain important clues about what you may be doing wrong.

Feed rates and bit performance are directly related to the depth of cut. Trying to remove too much material in a single pass can cause or increase burning and blow out ahead of the bit. It is always better to make multiple light cuts than fewer deeper cuts. Lighter cuts are far safer and produce much better results.

The Bottom Line

Routers extremely useful in the workshop, but they can also be very dangerous if used improperly, including the failure to employ adequate safety equipment, procedures and feed direction.

If you find yourself faced with a router-related task that you do not completely understand or do not have the proper safety equipment for, the only prudent course of action is to stop! Wait until you get the information and equipment to make the operation safe. The task will be there later, your fingers may not.

As with all power tools, the major cause of accidents is operator error. Not taking the time to be certain of feed direction with a router is dangerous, and could lead to severe injury. There are many woodworkers who have learned to pursue this hobby with a disability caused by a moment of lost concentration. Take the time to make sure you do not join those ranks.

Other Router-Related Stories

Reading the Grain Using Rabbet Bits Setting Up Rail and Stile Bits

Do you have a comment about this page? - Email Me!

Back to the Tips & Tricks List

LOOKING FOR A PROJECT? Check out our DIY plans we’ve made to help you build beautiful and sustainable items for your home.

A Beginner’s Guide On How To Use A Router

Are you ready to up you’re woodworking and DIY game using a router? Check out this beginner’s guide on how to use a router. From installing bits to proper routing direction, we’ve got you covered!

Disclaimer: This post includes affiliate links, and I will earn a commission if you purchase through these links. No additional cost for you. Read about our privacy policy .

A router is one of those tools that many people have never used as it takes a little more learning compared to other power tools. Even as experienced DIYers, we didn’t touch a router that we owned for many years until recently. While there are always multiple ways to achieve a final outcome on a woodworking project, routers can truly be a game-changer making it perfect grooves, professional-looking edges, and beautiful joinery. So don’t be afraid to learn how to use a router!

If you know your bit types and have a router on hand, it’s time to dive into the intricacies of using this powerful woodworking tool. We will guide you through the essentials for how to use a router, from safety measures and installing bits to height adjustments and routing directions.

Our Recommended Routers

Below are the routers we have, love using, and will use as examples below with how to use a router. We have several routers, both secondhand and new.

- Dewalt Fixed & Plunge Router Set – Its great height adjustment rings are easier than other brands we’ve tried.

- Bosch Trim Router – The advantage is the micro-adjust wheel that makes it easier to dial in exactly the right height for corner profiles.

- Porter Cable Fixed Base Router – we have a very old secondhand one that honestly can be a little annoying to adjust. However, this is a long trusted brand and the newer models look more promising.

These are less pricey options than something like a Festool router and can be a more budget-friendly option for DIYers, hobbyists, or newer woodworkers. For more, check out our recommended tools and products on our resource page .

Router Safety First

Before we dive into the practicalities of using a router, let’s emphasize the importance of safety.

- Eye and Ear Protection: Always wear eye and hearing protection to shield yourself from debris and the noise generated by the router.

- Dust Mask: Routers produce chips and dust that can be hard to capture with a vacuum, so protect yourself by wearing a dust mask .

- Clothing and Hair : Like with all spinning blades, avoid wearing gloves or loose clothing while using the router. If you have long hair, pull it back to prevent entanglement with the bit.

Now, let’s get started on using a router safely.

How To Use A Router – The Basics

Let’s go over the basics of how to use a router. We’ll cover installing a bit, setting the height, correct routing direction, and using guides and bearings when routing.

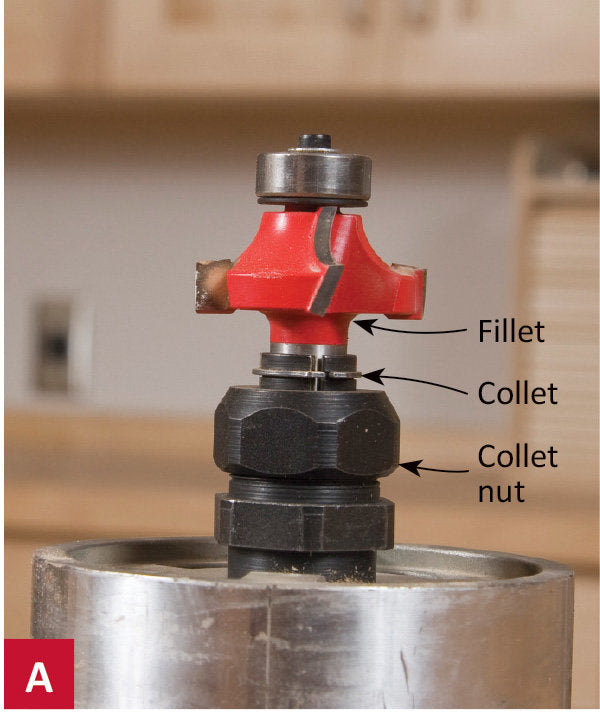

Installing a Router Bit

To start, you have to install the router bit. But first and foremost, always unplug your router before changing the bit. Honestly, do this with any blade on any tool for that matter to prevent accidental injury.

The shank of the router bit is inserted into the router’s collet. As you tighten the nut, the slits in the collet compress, securing the router bit within the tool. To install a bit, you will likely need a wrench. If your router has a collet lock button, you can press this button and spin the collet until the button clicks in and locks the collet in place.

While holding that button in, you can grab the wrench and loosen the nut. You don’t want to fully remove the nut, just loosen it. Then you can slide the chosen router bit in and tighten the nut back down.

If your router doesn’t have a collet lock button, it will probably have two flat spots on the shaft next to the collet nut like our Porter-Cable router. You’ll need to put a second wrench on these flats to keep the collet from spinning while you tighten and loosen the nut.

Right Hand Rule For Loosening Nut

You will want to make sure you are going in the correct direction to loosen the nut, and you don’t over-tighten and strip it. A good trick to remembering the correct direction to loosen the nut is by using your right hand.

You want the nut to come off, so you point your thumb up in the direction the nut needs to go. Then look at the way your fingers are curled. The way your fingers curl is the direction you will have to spin the nut to get it off.

Reducing Sleeve

For routers with a larger opening, a reducing sleeve may be needed for smaller bits. Some routers can accept ½” router bits and you will need a reducing sleeve to use smaller size bits. Our router with a ½” opening came with a sleeve for ¼” bits. You just need to install the sleeve in the collet, then install a bit and it tightens up perfectly.

If you live where the metric system is used, then your bits might be 6, 8, 10, or 12 mm. You can likely find an adapter sleeve for any of these sizes, but make sure you get one with multiple slits in it to get better compression and a more secure hold on the bit.

Bit Removal

When it’s time to change a bit, just reverse the process from before. Lock the collet, loosen the nut, and remove the bit. If you find that your bit is a little stuck, it can help to give it a gentle tap to free it and then pull it out.

Related – The Ultimate Guide to Router Bits: Exploring Types and Applications

Tips for Router Cut Depth and Width

To achieve the desired outcome, it’s essential to adjust the router bit’s cutting depth and width according to the task at hand. As a general rule of thumb, you should never cut deeper than the diameter of your bit in a single pass.

For deeper cuts, consider making multiple passes rather than pushing the bit too hard in a single attempt. This not only ensures a cleaner finish but also prolongs the life of your router bit. If kickback is likely in an area, make multiple smaller passes to work up to your final depth.

Setting the Height For Fixed Routers

Adjusting the height of the router bit is crucial for achieving the desired cut depth. The process varies between router brands. Here are three examples using our three routers.

Porter Cable

Starting with our older router, the first thing you have to do is release the clamp holding it in place. This usually comes in the form of a latch. Once that is released, there is usually an adjustment screw somewhere. Ours has this plastic screw that turns a metal shaft inside it. This one has seen better days and the mechanism often gets jammed. So we work in the direction of gravity, and turn the knob until we get to the desired height, then lock it down.

Our Dewalt fixed base router is much more convenient. You release the latch, then spin the ring to dial in the height up or down and lock it in. To get a more precise measurement, you can align the 0 on the yellow ring to the arrow on the router, then turn the adjustment ring to get the dimension you want and lock it down.

Trim Router

Our trim router is pretty unique. Bosch’s trim router has a three-position knob. In the top position, the base is completely loose and you can slide it up and down freely. In the second position, it engages with the thread inside the base. Then you turn the wheel to finely adjust the position height of the bit. Finally, you turn the knob to its third position to lock it in place.

Height & Depth Adjustments for Plunge Routers

We also have a plunge base for our Dewalt router . A plunge base operates completely differently from a fixed base router, but the operation of setting the height between brands is pretty similar.

In its simplest form, a plunge base allows you to push the router down to a specific depth and then lock it at that position. Ours has a lever on the backside that you can toggle. What is cool is where you go from here.

If you want to go to the same depth in multiple locations, you can drop the depth stop and lock it in place. Some routers will have a screw down here, or a dial up above to finely adjust the position of the depth stop in case the original setting was slightly off. Once this is set, it will limit the depth of the plunge and you can get uniform results in multiple locations.

Using Depth Stops To Make Deeper Cuts

Say you want to make a pocket that is ½” deep. You won’t want to take that in one deep plunge with the router. What you can do is plunge the bit down until it is touching your surface. Drop your depth stop so it is touching the highest incremented step, and lock it in place. Then you turn the stop one click. That’s the first pass and on most routers, it is probably ¼”. You make that pass, then you turn it again, and now you are at ½”.

Routing In the Correct Direction

Understanding the correct direction to move the router is crucial for safe and effective routing. Like anything else in the workshop, the key to safety is control .

You see, router bits cut wood by spinning blades. These blades have to exert force on the wood fibers to shear them. If you are routing a groove in the surface of a piece then both sides of the bit are touching wood and direction doesn’t matter as much. The problem comes when you are on the edge of a piece.

With edge routing, one side of the bit is touching the wood and exerting force while the other side isn’t. This imbalance makes the router want to pull itself along the piece. This can cause the router to run away from you, which can be dangerous. And in the case of a router table, it can quickly pull the piece along the blade which may catch an unsuspecting finger. To cut safely, it is better to resist this motion and move the router in the opposite direction that it wants to pull .

Right Hand Rule For Routing Direction

The easiest way to determine this direction is with another right hand rule. Use your right hand to determine the direction based on the position of your thumb and index finger relative to the edge of the workpiece.

On your right hand with your palm facing upwards, hold your thumb and index finger flat and middle finger out pointing upwards. Then turn your palm over and pretend your palm is the base of the router and your middle finger is the router bit. If you touch your thumb to the edge of the workpiece that you want to cut, then your index finger will point in the direction you need to go. This works regardless of whether you are on the outside of the piece, the inside of the piece, holding the router by hand, or using a router table.

When To Break The Direction Rule

Now let’s talk about when to break this routing direction rule. If you are routing along the edge of a piece, there is a possibility that the blade’s teeth will catch the wood fibers and split them instead of shearing them. This is especially true if you are taking larger passes, or working with wood that is prone to splitting like the Alder we used on our DIY headboard . And if the wood isn’t prone to splitting, the blade may catch and that energy will cause the router to kick back.

In certain situations, like edge routing, climb cutting can prevent tear-out and kickback. Climb cutting means allowing the router to go in the direction it wants to. Because you are now going the opposite direction, instead of cutting in the direction of the wood grain, the teeth are now cutting perpendicular to the wood grain. So they shear the wood grain and then scoop it out. You have to be careful doing this and have a firm grip on the router or piece. The router will want to pull, but you have to resist that. Climb cutting can save your piece so long as you do it carefully.

Related – Hubby How To – Modern DIY Platform Bed Frame

Using a Guide

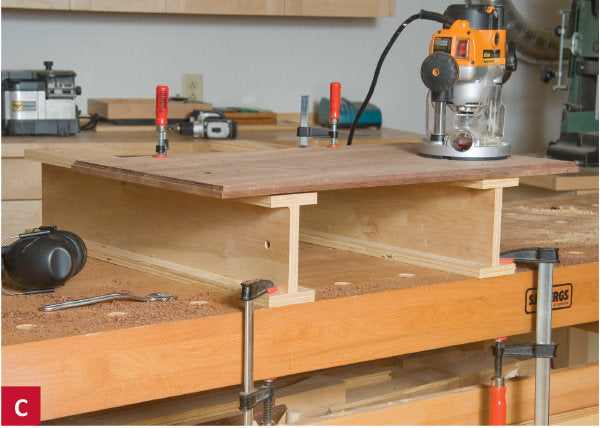

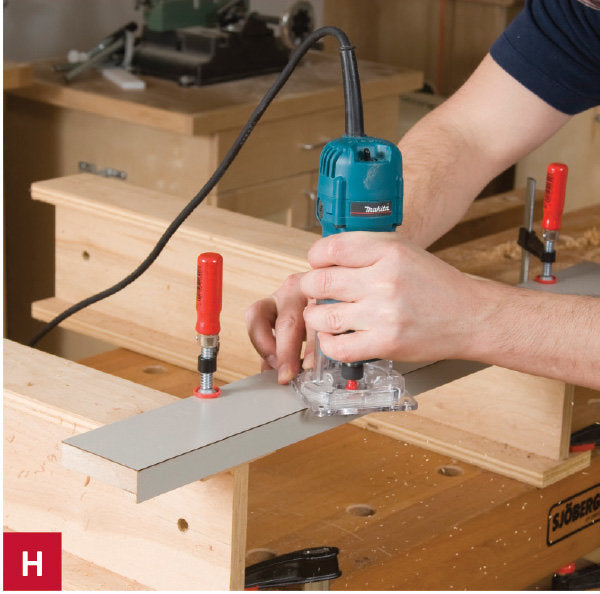

A common use for a router is for routing slots and grooves. To do this, you need a guide to ensure you have a straight line. Some routers come with an edge guide accessory, but those aren’t really necessary. All you need is a straight edge. Even the factory edge on a sheet of plywood will do the trick.

To cut a groove with a guide, first start by placing the router where you want the groove to be located. Then bring a straight edge up until it’s touching the edge of the router’s round part on the base, and clamp it down. After that, use the router to check the other end of the groove, and then clamp that side of the straight edge down as well. Now if you route along this line, you will get a perfectly straight line.

Utilizing Router Base Concentricity

The trick here is that you are using the round part of the router base. This works because the router bit is concentric to the base plate. This means it is always the same distance from this circular edge. If you twist the router or bobble while making your cut, the line will stay straight. If you used the straight edge of the router base here instead, then every little bobble would show up in the finished cut.

Tip – Straight bits work great for cutting slots and grooves, but we’ve found that a nice downcut spira l bit enables us to do grooves in plywood that result in almost no tear-out. This means less cleanup and sanding work later and no ruined workpiece that’s hard to repair. It’s totally worth the little extra cost for the bit.

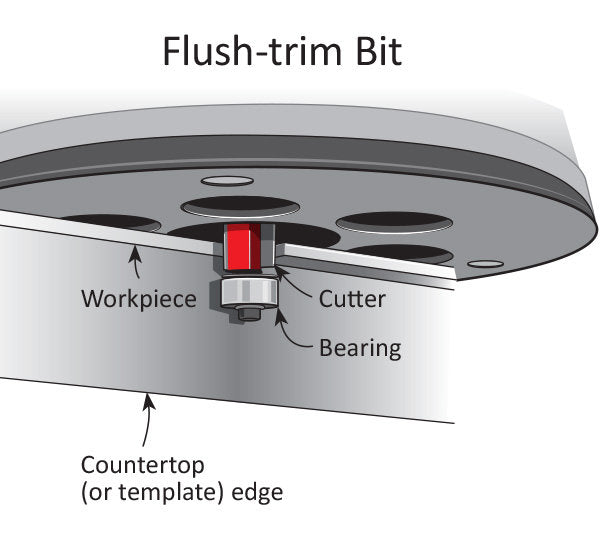

Using a Bearing

There are six different types of router bits and each has a specific purpose. Several bits use bearings to reference the edge of a piece. These bearings make it extremely easy to get consistent and perfect results from your bits. However, there are three things that you need to keep in mind when using these bearings.

Proper Positioning

First is proper positioning for flush trim and template bits. You want the bearings to ride perfectly along the template or other surfaces, but you don’t want to risk cutting into those surfaces. So only set the position of the bearing as close as possible to the surface you intend to cut. The last thing you want to do is shave off part of your template.

FAQ – Aren’t the bearing and blades exactly the same size, so why would it cut into my template? There are two possible reasons this could happen. The first is a manufacturing error. They may not be exactly the same size. However, this is more common when using cheap bits. The second possible reason is an incorrect technique.

Gentle Pressure

The second thing to keep in mind is to use gentle pressure. You want to hold the bearing against the side of the piece, but this should be a gentle motion. If you press too hard, you will cause deflection in the router bit’s shaft, and you’ll end up with a bad cut. Let the router bit do the work. You are just there to guide it.

Maintain A Flat Router Base

Lastly, you also want to be sure to keep the router base flat on the surface of the piece. You don’t want to let the router tip or it will mess up the cut. If you have two handles, it is good practice to keep one over the surface of the wood and pushing down, while you use the other to guide the router around.

Many trim routers have a place by the base for you to put your fingers. Then you can rest your hand on the piece and apply downward pressure to prevent tipping as you work your way around the piece.

Related – How To Use Router Guide Bushings For Inlays

More Router Guides & DIY Projects

We’ve covered the basics of how to use a router in this guide to help you enhance your woodworking skills and achieve professional results. You can learn more from our other router guides too. Now it’s time to get started on a DIY project!

So check out more of our DIY projects articles for inspiration or grab some DIY plans from our Site Shop or Etsy Shop !

- Hubby How To: DIY Flipping Workbench

- Hubby How To – Modern DIY Platform Bed Frame

- Hubby How To – DIY Modern Headboard With Floating Nightstands

- Hubby How To: DIY Hanging Daybed Swing Plans

- Hubby How To: DIY Stacked Rain Barrel System

15 Awesome DIY Projects At Home You Can Do

A simple eco-friendly checklist for spring cleaning, interior door makeover: easy diy project at home.

Hope this guide helps you get started with using a router! Let us know what projects you are going to do with a router in the comments below!

Disclaimer: This post includes affiliate links, and I will earn a commission if you purchase through these links. Please note that I’ve linked to these products purely because I recommend them and they are from companies I trust. There is no additional cost to you .

Similar Posts

How to use router guide bushings for inlays.

Curious about how to use a router guide bushing for an inlay? In this post, we’ll cover how to determine the size of guide bushings needed and how to use…

How To Make A DIY Garland Using Power Tools

Want a faster way to make party or holiday garlands? Using scissors and hole punches are a thing of the past. Check out how to make a DIY garland using…

Why Rubio’s SheenPlus Is Better Than Polyurethane

Looking for a Polyurethane alternative? Or simply want to increase the sheen on surfaces? We’ll show you why we prefer Rubio Monocoat’s SheenPlus over polyurethane, when to use it, how…

23+ Gifts For DIY Lovers That They’ll Actually Use

Gifting will always be around as it’s a way people celebrate a life event or show love and appreciation to another person. However, people are unique and can be hard…

A Comprehensive Guide On How To Use A Drill

Looking to understand how to use a drill like a pro? Power drills are a staple tool in every DIYer and woodworker’s toolkit. We’ll cover all you need to know…

Hubby How To: Custom DIY Storage Shelves

Most of us always have some storage totes or seasonal decor stuffed away somewhere. Well, the best way to organize items like this in an efficient manner is by building…

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

- svg]:stroke-accent-900"> 826K

- svg]:stroke-accent-900"> 622K

- svg]:stroke-accent-900"> 246K

- svg]:stroke-accent-900"> 45K

How to Use a Router the Right Way

By Timothy Dale

Updated on Dec 31, 2022 12:55 AM EST

12 minute read

We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Woodworking can challenge your DIY skills and encourage creativity. However, sticking to the most basic tools can be limiting. It’s helpful to familiarize yourself with different tools of the trade to keep your options open, and one such power tool is the woodworking router .

Using a router table or a handheld router, woodworkers can make cutouts, sharp edges, rounded edges, joints, decorative cuts, rabbets, and dadoes, and they can even make duplicates from a pattern. There are many router projects woodworkers can tackle with a standard cutting bit, but switching to one of several router bit shapes to create unique designs and intricate patterns can open up more customization options.

If you want to learn how to use a router the right way, this guide has you covered.

Important Router Parts

Knowing how to use and maintain a router tool properly begins with understanding the key parts of a router and how they function.

- Motor: An electric router typically has a vertically mounted motor that converts electrical energy into mechanical energy to drive the cutting blade.

- Collet: A collet is essentially a steel sleeve enclosed within a locking or retaining nut that secures the router bit in the router while working.

- Base: Handheld router bases have a hole in their center, through which the router bit protrudes to cut into the target material.

- Speed control: This dial can be used to increase or decrease the router cutter’s operating speed.

- Depth stop: A depth guide that can be preset to a specified depth for making cuts at consistent depths or stopping the router from being lowered too far into the material.

- On/off switch: A switch or trigger that turns the router on or off.

4 Types of Routers to Know

There are multiple common router types, including fixed-base routers, plunge routers, trim routers, and router tables.

1. Fixed-Base Router

The most common type of handheld router is known as a fixed-base router . With this type of router, the position of the router bit remains fixed. For instance, if you set the cut depth to ¼ inch, the router bit will only protrude past the base ¼ inch until the depth is changed. Fixed-base routers are designed for a wide range of shaping and edging jobs. A fixed-base router is a good option as a first router to get started, since it is relatively easy to learn how to operate and often costs less than plunge routers or router tables.

Our Recommendation: Bosch 2.25 HP Electronic Fixed-Base Router at Amazon for $149 The 12-amp motor and adjustable speed dial allow users to find the right pace for a given project, and the hardwood handles add comfort and stability.

2. Plunge Router

A plunge router tends to provide greater ease and control when woodworking because the tool’s base can rest on the material surface while the router blade is lowered for the cut. This is in contrast to a fixed-base router, where the bit protrudes from the bottom of the router to a set depth. Experienced woodworkers can use plunge routers to create dovetail, groove, dado, and mortise cuts, as well as deep through cuts. Just make sure to set the depth stop to avoid inadvertently cutting deeper into the material than originally intended.

Our Recommendation: WEN RT6033 15-Amp Variable Speed Plunge Woodworking Router at Amazon for $87.03 This plunge router has a variable speed setting for improved control, edge guide for accuracy, and protective carrying case.

3. Trim Router

Similar to a fixed-base router, a trim router is a smaller tool best suited to cutting through thin pieces of wood or laminate. Most trim or laminate routers have small, light-duty designs and are easy to guide with one hand. Expect these tools to have smaller motors than fixed-base and plunge routers, so they may not be the best general-purpose tool option.

Our Recommendation: WEN RT1460 6-Amp Handheld 1/4-Inch Variable Speed Laminate Trim Router at Amazon for $53.97 A guide fence for straight cuts, trim guide for curved cuts, and variable speed dial help this trim router produce optimal results.

4. Router Table

One drawback of a handheld router is that the tool relies on the user for control and accuracy. If the router slips, shifts, or kicks back, material can potentially be cut, nicked, or otherwise damaged. However, a router table can help improve control and accuracy by providing a stationary position in which the router tool can sit. Once attached to the router table, the router bit sticks up out of the table surface. The material can then be guided into the blade for a variety of jobs, including shaping trim, cutting rabbets, or making tongue-and-groove edges.

Our Recommendation: SKIL 10 AMP Fixed Base Router Kit at Amazon for $199 This SKIL router bundle includes a router table with built-in bit storage and a 10-amp fixed-base router tool for smooth, precise routing.

Router Safety Tips

Consider these key safety tips before picking up a router, so you can stay safe while you work.

- Keep a firm, two-hand on the router, especially when the bit first comes in contact with the material. This also helps to keep control of the tool if it becomes stuck in the material and kicks backs while in use.

- Make sure to disconnect the power to the router when changing bits, performing router maintenance, cleaning the tool, or mounting router attachments.

- Make personal protection a priority when using a router. Put on long pants, a long-sleeve shirt, closed-toe shoes, gloves, safety glasses, a dust mask, and consider using ear plugs or similar hearing protection.

- Regularly inspect, clean, and maintain the router to ensure that it functions properly while you work. Replace worn-out parts, discard old bits, and make repairs as necessary to keep the tool in good condition.

RELATED: The Best Router Lifts for Your Workshop

Initial Setup and Calibration

An initial setup, inspection, and speed calibration is necessary before attempting to use a router. Typically, a 2 horsepower (hp) router is suitable for most DIY and home woodworking jobs. You can also get small, 1.25hp routers for trim, or full-size 3hp routers if you feel the need for extra power. Before using a new router, consult the owner’s manual to get a detailed breakdown of the parts and controls.

- Disconnect the power and turn off the power switch before changing bits.

- Select the appropriate router bit for the job by checking the type, shank strength, cutting length, cutting diameter, and sharpness of the bit.

- Set the router bit depth to ensure that you don’t cut deeper into the material than intended.

- Make sure the set speed is suitable for the target material.

- Test the bits, attachments, clamps, and locking devices to ensure that they are properly tightened and secured.

- Clamp the target material to prevent it from shifting while you work.

- Clear the immediate area of any people or pets.

- Connect the power and line up the router bit to make the initial cut.

- Set up a guide fence to make straight cuts in the material or use a trim guide for curved cuts.

- Do not bring the router bit into contact with the material until it has had enough time to speed up, otherwise the bit may kick back instead of cutting through.

How to Use a Router for Cutting Decorative Edges

A common use for routers is to cut decorative edges into a project to give it a more intricate finish. Follow these steps to learn how to cut decorative edges into the target material with your router.

STEP 1: Select a suitable bit, set the depth, and position the router.

The bit for the job typically depends on the type of cut desired. For cutting straight through wood, a basic straight bit is the best choice, but if you want to make round edges, then it’s better to go with a round-over bit. There are a wide assortment of router bits available for making decorative edges. Keep in mind that the type of decorative edge is determined by the type, size, and shape of the router bit. Consider which bit would be right for your project and insert it into the collet.

Check the depth of the bit and set it to the desired level, then line up the router with the material. It’s important to note that for the best results, you may need more than one pass with the router to get an accurate cut. The router bit should be set to a shallow depth to remove a small amount of material with the first pass. Reset the depth to take off more material with the second pass. Repeat this process as necessary for a smooth finish.

STEP 2: Turn on the router and begin cutting the material.

Connect and turn on the router, then let the bit get up to speed. Do not touch the bit to the material before it has had time to speed up or it might kick back. When the bit is at the set speed, move the router to start cutting into the material.

Keep in mind that the router direction matters. Always push the router from left to right for routing the perimeter of the material and push the router from right to left if you are routing an interior cut. If left and right are a bit confusing, you can also think of it in terms of a clock. Push the router in a counterclockwise direction when you are routing the perimeter and push the tool in a clockwise direction when working on an interior cut. This means that the router should be moving against the rotation of the bit.

However, in some cases, the grain might pull away when you attempt to move the router in the usual direction. In these instances, you will need to use climb-cutting to finish the cut. With climb-cutting, the user pushes the router with the rotation of the bit instead of against it.

STEP 3: Make a pass with the router to cut the decorative edge.

As the router bit is cutting into the material, move the router along the edge of the material to start creating the decorative edge. Begin with the grain sides first because if you get a tear-out on the corners, you can clean them up as you route the other two sides. Move the router at a steady pace while routing in a counterclockwise direction for perimeter cuts and in a clockwise direction for interior cuts.

STEP 4: Reset the depth and route the final pass.

After the first pass is complete, reset the depth and route the next pass. Repeat this process as necessary until you route the final pass. Some projects will require only two passes, though others may require three or four to get the desired results.

RELATED: The Best Woodworking Tools

How to Use a Router for Cutting Rabbets and Dadoes

A rabbet refers to a step-shaped or L-shaped cut along the edge of a piece of wood, creating a shoulder in the material. It’s typically made to form a match to the edge or tongue of another piece to create a rabbet joint. Another common cut that you can do with a router is called a dado. This refers to a grooved cut in the face of a board. It’s usually cut across the grain and is intended to fit the edge of another board to form a dado joint.

To cut a dado or a rabbet, it’s usually best to use a straight or rabbeting router bit. Set the desired depth for the project, but make sure that the initial depth is more shallow than the final depth. The purpose of this shallow setting is to remove a small amount of material with the first pass before resetting the depth for a subsequent pass. By making cuts with more than one pass, a woodworker helps reduce the chance of burning the wood, wearing out the bits, or damaging the piece.

Line up the router and bit with the area that will be cut. Consider using one or more guide fences to ensure that the cut is straight.

Connect the router, turn on the switch, and allow the router bit to speed up. Do not touch the router bit to the material before it has reached the set speed because the bit may get caught or kick back off the material if it is not operating at a high enough speed. Once the router bit is up to speed, move the router bit to the material to start cutting.

For a rabbet joint, push the router counterclockwise across the edge of the material to cut an L-shaped shoulder. If you are cutting a dado, push the router counterclockwise across the face of the material to create a grooved cut in the face of the board.

STEP 3: Reset the depth and route the final pass.

After making the initial cut, reset the depth, and push the router through a second pass to remove more material. Depending on the desired depth, you may only need two passes to complete the rabbet or dado cut, but cuts might require three or four passes to get the desired result.

Other Router Projects for Beginners

Beyond finishing edges and routing rabbets and dados, here are a few more common applications for this versatile power tool.

Shaping stylish molding : Decorative molding is perhaps the most interesting thing a router can create. Using different bits, you can craft everything from simple rounded moldings to more elaborate Roman ogee or beaded patterns for doors, windows, baseboards, or chair rails.

Recreating patterns : Routers can be used to cut patterns, grooves, and designs across multiple pieces of wood. For instance, if you have a broken table or other piece of wood, you can use the router to “trace” the outline of the original piece and re-create it as many times as you like. Routers can also be used on flat pieces of wood to trace intricate designs or lettering.

Recessing door hinges : Routers can be used with a jig to cut space for recessed door hinges or lock faceplates. Recessed hardware yields a more finished appearance and smoother operation.

Router Maintenance Tips

One of the most important factors to keep in mind is that a router requires regular maintenance to ensure that it will continue operating properly. Use these router maintenance tips to ensure that your router lasts for years.

- Don’t clean a router by blasting with a burst of high-pressure air from an air compressor. This often can force dust and dirt further into the machine. Instead, use a shop vac to clean out the router after every use. This will prevent sawdust from being pulled into the router by the cooling fan and creating future problems.

- Corded routers can put a lot of strain on the electrical wire as it constantly winds, unwinds, shifts, pulls, bends, and is maneuvered for better access to projects. Make sure to inspect the power cord for any areas that show signs of wear or significant strain. Repair or replace damaged parts before using the tool again.

- Cordless routers can also develop problems due to the constant insertion and removal of the battery packs. Check the batteries, battery compartment, and the battery contact areas for wear and tear. Make repairs or replace any parts that are too worn out to safely use.

- Routers typically have a plastic facing on the base that is intended to prevent the router from scratching or marking the surface of the material as you work. However, over time this facing can become dusty, grimy, or worn, so you need to ensure that the facing is clean and in good condition before using the router.

Final Thoughts

Handheld routers come in a small variety of types and can be used for a wide assortment of cuts, grooves, joints, and decorative edges. By learning how to use a router, amateur woodworkers and DIYers can take their skills to a new level with a powerful tool that can cut straight lines, shape decorative edges, and create connections between two or more pieces of wood with intricate joints and detailed joinery.

Like most power tools, users need to be aware of the potential dangers and risks of these tools to avoid damages and personal injury. Take router safety seriously and make sure to stay on top of regular maintenance tasks, like inspecting and cleaning the tool before and after every use.

RELATED: The Best Power Tools and DIY Products Tested by Bob Vila Experts

Your Biggest Questions About Heat Pumps, Answered Your Biggest Questions About Heat Pumps, Answered

By Tony Carrick

Anker’s New Home Battery Tower Is a Sleek, Modular Step Toward Complete Energy Independence Anker’s New Home Battery Tower Is a Sleek, Modular Step Toward Complete Energy Independence

By Chase Brush

The Right Way To Use a Router

Many woodworkers consider the router to be the most versatile portable power tool in the shop. Here's why.

Gear-obsessed editors choose every product we review. We may earn commission if you buy from a link. Why Trust Us?

We love the Bosch's beechwood knob handles. But more impressive is the whopper of a 2 ¼-hp motor that allows you to control its speed with the turn of a red thumbwheel. The Bosch doesn't roar. With a sharp carbide bit, that big motor just purrs as the router leaves a gleaming, crisply shaped edge in its wake. It's a wonderful thing to behold, and as power tools go, it's a classic that makes every amateur look good.

Move to the Right

The biggest mistake novice woodworkers make is advancing the router in the wrong direction. It's easier to practice the correct technique than it is to explain it, but here goes: First, always move the router against the rotation of the bit. That allows the bit to cut into the work, giving you full control over the tool. If you advance the router in the same direction as the bit's rotation, the router will run along the edge of the workpiece and you'll have to fight to keep control.

When looking straight down at the top of a router, the bit rotates in a clockwise direction. That means you should move the router from left to right, but—and this is important—that's only true when the router is positioned in the middle between you and the workpiece.

For example, if you were routing the edges of a board, you'd move the router from left to right across the edge closest to you. But, when routing the opposite edge, the one farthest away, you'd advance the router from right to left. That's because the workpiece--not the router--is now in the middle. In that position, the router is moving right to left, but it's correctly cutting against the rotation of the bit.

Be the Co-Pilot

One of the best and safest ways to begin routing is to use router bits fitted with ball-bearing pilots . The bearing rides along the edge of the workpiece, effectively keeping the bit on course and in control. Simply set the depth of cut and you're ready to rout. There's no need to attach an edge guide to the router or straightedge fence to the work. The bearing alone will ensure the bit cuts to the proper width. Nearly all edge-shaping and trimming bits are available with ball-bearing pilots, including rounding-over, Roman ogee, chamfer, rabbeting, and flush-trimming.

Take the Guided Tour

Once you've mastered basic routing techniques, create a precise milling machine by equipping your router with a guide bushing and straight-cutting bit . A guide bushing (aka template guide) is simply a steel collar that mounts onto the router's base. Protruding from the collar is a short steel tube through which the bit extends. The tube is guided along the edge of a template, allowing you to quickly cut boards to virtually any size or shape. Here's a brief description of how to use a guide bushing:

Start by cutting a template to the desired shape out of plywood, MDF or hardboard. When making a template, take into account the offset between the outside edge of the bushing and the cutting edge of the bit; a distance that's usually about 3/16 in. Also, be sure to sand the template edges perfectly smooth. Otherwise the bit will transfer any imperfections to the workpiece.

Clamp the template in place, then advance the router into the workpiece. Be sure to keep the guide bushing pressed tightly against the edge of the template. Guide bushings are useful for routing curved, irregular shapes, but also for precisely cutting hinges and mortises. You can buy guide bushings individually, but it's usually more economical to buy a multipiece set .

Turn it Upside Down

Mounting your router upside down in a router table greatly expands the tool's capabilities, making routing easier and safer. With the tool held securely in place, you can use both hands to safely feed the stock into the bit. And since the bit is clearly visible, you can see exactly what you're doing. (That's not always possible with handheld routing.) Router tables are especially useful when milling smaller parts, cutting stopped grooves, or using large-diameter bits. In fact there are some bits, including certain raised-panel bits, that should only be used in a router table.

You can make your own router table easily enough, and many table saws have extension wings that accept a router. But for most DIYers, a store-bought router table is the best option since it comes ready-to-use with all the necessary equipment, including an adjustable fence, miter gauge, On/Off switch, dust-collection port and bit guard. However, router tables typically don't come with a router, so check the specs before buying one to ensure your router fits the table.

Claim Your Door Prize

Building traditional frame-and-panel cabinet doors is virtually impossible without a router. The stiles and rails that form the door's frame are joined together with tight-fitting coping and sticking joints. The door's raised panel has beveled edges that fit into shallow grooves cut in the frame parts. The frame is assembled with glue only, so all the joints must be milled precisely for the parts to properly fit together. And the router is the tool to use to cut these joints. You'll also need a router table to safely make the cuts.

Rail-and-stile bits are sold in sets, and raised-panel bits are sold individually. You can also buy cabinetmaking sets , which include all three bits.

Dovetail Details

There are few wood joints as strong or as beautiful as a dovetail. Wedge-shaped pins fit snugly into dovetail-shaped tails, effectively locking the two boards together. Dovetail joints are commonly used to build drawers, blanket chests and jewelry boxes.

And while it is possible to cut dovetail joints by hand, using a router and dovetail template is precise and much faster. A dovetail template is essentially a vise that's equipped with adjustable metal fingers. You clamp the tail board into the template and then use a dovetail router bit to cut the tails. Next, install the pin board into the template and use a straight router bit to cut the pins. It's a little tricky getting all the pins and tails properly aligned initially, so make a few test cuts in scrap wood before routing the workpieces.

Four Ways to Rout

Straight groove.

Grooves appear everywhere in woodworking. For example, use one to seat a drawer bottom in drawer sides, front and back. To make a groove with a router, use a fence accessory. Set the fence the required distance from the bit and set the bit's depth. Not much more to it than that.

Dovetail Joint

Dovetailing with a router requires two things: a dovetail template and a corresponding bit. You perform two operations with the template. With one you cut the dovetail and the other you cut the pins. Push the two parts together with wood glue between them and you have a nearly unbreakable joint.

Routered Edge

A router can cut any decorative edge on a workpiece, from a simple rounded corner to a series of curves in a single pass with a Roman ogee bit. These shaping operations may be guided by a ball-bearing bit or a bit minus the bearing. With either method, take a test run on scrap before working on the actual piece.

Template Cut

The fastest way to make exact duplicates of a part, such as four bracket feet for a blanket chest, is to use a pattern and a top-bearing straight bit. The bearing rolls along the pattern as the straight bit carves the wood.

Joe Truini is a former carpenter and cabinetmaker who writes extensively about remodeling, woodworking, and tool techniques. He's the author of eight DIY books and is a long-time contributing editor to Popular Mechanics .

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.

.css-cuqpxl:before{padding-right:0.3125rem;content:'//';display:inline;} Tools Reviews .css-xtujxj:before{padding-left:0.3125rem;content:'//';display:inline;}

The 9 Best Pole Saws for Every Tree-Pruning Job

The 4 Best Garbage Disposals, Tested

The Best Cordless Impact Wrenches

The 8 Best Battery Stringer Trimmers for Lawn Care

Amazon Warehouse Craftsman Tool Sale: Get 50% Off

The 9 Best String Trimmers of 2024

The Best Reciprocating Saws for Powerful Cuts

The Best Portable Table Saws

The 5 Best Zero-Turn Mowers of 2024

The Best Dust Collection Systems for Your Shop

The Best Electric Mowers of 2024 for Any Yard

Select store

How to Use a Router

Intermediate

Under 2 hours

Learn how to use a router to widen your DIY horizons. Using a wood router to shape and cut wood lets you finish edges for a professional look. You can use a router to create patterns and grooves in wood.

This guide will outline how to use a router. There are two main types of routers: table routers and handheld routers. These steps will apply primarily to how to use a table router. It’ll cover safe usage, router mounting and operation. You’ll also learn how to tighten, loosen and remove a router bit .

Safety Tip: Always read the manufacturer’s instructions prior to operating any tools.

Router Basics and Safety

Router mounting and router types, how to cut grooves and rout edges, how to change router bits, minimize splintering when routing, how to use a router fence, tips for router use.

What does a router do? It allows you to make:

- Customized cuts to shape the edges of a board

- Finished laminate edges

- Tongue-and-groove or other special joints in woodworking

- Detailed mouldings and trimwork

A handheld router or table router is a good choice for small-scale DIY woodworking projects. It helps you get used to the motions and methods of the tool.

First and foremost, consider safety. This includes both protective gear and best practices for router use:

- Always wear safety glasses and ear protection . Routers are loud and splinters and sawdust will fly.

- Cut-resistant work gloves are also a good idea when you’re learning how to use a router.

- Remove jewelry.

- Avoid wearing loose clothing.

- Securely pull back long hair.

When you’re geared up, know how to use a table router safely:

- Hold onto both handles when operating it. This helps you maintain control of the tool.

- Plan your cuts. You want to be out of the way when the router leaves the wood or starts cutting.

- Make several shallow passes instead of a single deep pass. Each pass is one run of the wood through the router. It’ll protect you, your project and your router.

Follow the same tips when learning how to use a trim router. Trim routers are smaller versions of wood routers. They’re used for trimming laminate.

You can mount a router to a workbench or a router table. Attach a router to a workbench with a shop-made jig. If you have a router but need to purchase a table, make sure they’re compatible with each other.

Router tables have a hole for the bit. They allow for adjustments to the bit height. Tables also have a router fence and a dust port. The dust port can connect to a shop vacuum or dust collector.

Router Mounts and Routers Vs. Shapers

Mounting a router upside down underneath a table turns the router into a small shaper. This is a versatile tool to make moulding for a custom trim work piece.

Shapers and routers are quite similar. One difference is shapers have larger bits, called cutters. These cutters are strong enough that a single cut may be enough. A shaper is more powerful than a router. It can make it through huge projects without faltering. Some may consider the shaper to be an upgrade from a table router. Shapers are sometimes another name for huge industrial routers.

Table Routers Vs. Handheld Routers

The router on a router table is upside-down compared to a handheld router. Feed stock from right to left along the fence. Stock is a board or piece of wood.

Always feed the wood the opposite direction of how the bit is turning. In general, this means:

- Feed counterclockwise on a router table with the bit facing downward. This is an uncommon setup.

- Feed clockwise on a router table where the bit sticks up from the table. Most table routers are like this.

- Feed counterclockwise when using a handheld router.

Sometimes you may guide a stock against a piloted bit instead of a fence. In that case, feed the stock so that it travels clockwise around the bit while cutting.

Understanding the answer to “What does a router do?” means properly using the tool. You could run a router quickly along a board to get done faster. However, if you take your time, the project will turn out much better.

As with many power tools, practice makes perfect:

- Try your technique on scrap wood to get used to the router. If possible, use the same wood and bit you’ll be using on your project.

- Always make shallow test cuts to determine a safe feed rate.

- Figure out the cut-speed and amount of wood to remove with each pass.

- Once you’re comfortable with the tool, use it to finish your woodworking.

- Use a push stick when your wood is nearly through. It will protect your fingers from the bit.

Safety Tip: Recklessly running wood through the router could injury you, the project or the tool. Always carefully run the wood against the spin of the blade. Slow and shallow cuts are key.

Feed a table router slowly from right to left for best results. The wood goes in against the direction the blade is spinning. You should feel light to moderate resistance as you work. The resistance means the router is doing the work. Feed speed is determined by the wood and the type of cut you’re making.

If you push the material with the spin of the blade, it’s called climb cutting. This is dangerous and should be avoided. The blade might pull the material from your hands. It could even pull your hands or fingers into the blade.

If you’re working too fast, you’re force-feeding the router. Force-feeding stock means the bit touches the wood fewer times per cutting pass. Avoid doing this. It often bogs down the machine. Put another way, it slows down your router in a way that you can hear it struggling.

Force-feeding gives a rough surface. It also leaves wavy lines called chatter marks. They’re unattractive and you’d need to sand them off for a smooth finish. Working slowly means you’ll have less to polish up when you’re done.

Feeding wood too fast could give you these unwanted results:

- Snap the bit off at the shank

- Damage your router

- Overheat the bit and char the wood

- Give you an uneven cut and chatter marks

- Damage your project

Make shallow passes for smoothest results. Try to resist the urge to make a cut in a single pass. The larger the bit, the deeper the cut. Work even slower on harder materials. For a successful deep cut, you’ll need to make more shallow passes.

Read on for specifics on using a router to smooth edges or cut grooves in wood. These are two common uses for a table router or handheld router.

To cut a groove with a router, follow these steps:

- Set up the cut. Use a guide fence if needed.

- Adjust the bit so it's cutting somewhere around 1/4-inch deep.

- Run the wood through the router to make the cut.

- Raise or lower the bit and repeat until you've cut a groove to the depth you want. A handheld router needs the bit lowered. Raise the bit on a table router where the bit faces upward.

Tip: Listen to the machine. Any change in sound gives you clues. The pitch changes when you're working the machine too hard by feeding too fast. The router may also sound different when your bit is dull and needs replacing. Over time, your ears can help guide your router technique.

Follow these steps to rout the edge of a board with a bit that has a bearing:

- Set the bit to the final depth of cut and leave it there.

- Start routing. Hold the router bearing near the edge. The bit should only cut 1/3 or 1/4 of its final width.

- Rout the edge. Gently run the board through.

- Move the bearing in so it’s half the distance to the edge and repeat.

- Don’t worry about a wavy edge for the first few passes. It’s not possible to make a straight line as you cut a base.

- Clean up the edge in the final pass. Guide the pilot along the edge of the board to smooth it.

Tightening or loosening the router bit depends on the individual router. Routers have either a dual-wrench collet or a pin lock collet. The collet is the nut that holds the bit to the router. Some routers require two wrenches to tighten or loosen the bit. Others need only one wrench.

On a router without a locking shaft, you’ll need two wrenches. One wrench holds the base plate steady or arbor shaft. The other loosens the collet itself. Most dual-wrench collets are on large routers, such as table routers.